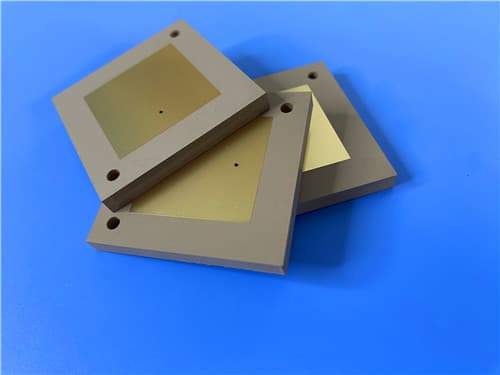

TP960 2-Layer 19.6mil High-Dk Thermoplastic PCB with ENIG Finish

1.Introduction

TP material is a unique high-frequency thermoplastic material in the industry. The dielectric layer of TP-type laminates consists of ceramics and polyphenylene Oxide resin (PPO), without fiberglass reinforcement. The dielectric constant can be precisely adjusted by adjusting the ratio between ceramics and PPO resin. The production process is special, and it has excellent dielectric performance and high reliability. TP refers to the smooth surface material without copper cladding, TP-1 refers to the material with copper cladding on one side, and TP-2 refers to the material with copper cladding on both sides.

The dielectric constant can be arbitrarily selected within the range of 3 to 25 according to circuit requirements, and it is stable. Common dielectric constants include 3.0, 4.4, 6.0, 6.15, 9.2, 9.6, 9.8, 10.2, 11, 16, and 20. The dielectric loss is low, and the loss increases as the frequency increases, but the change is not significant within 10 GHz. The corresponding part numbers are TP300, TP440, TP600, TP615, TP920, TP960, TP980 etc.

2.Key Features

Dielectric constant (Dk) of 9.6±0.19 at 10GHz

Dissipation factor of 0.0012 at 10GHz

Low TCDK at -40 ppm/°C, -55°C to 150°C

CTE x-axis of 40 ppm/°C, CTE y-axis of 40 ppm/°C, CTE z-axis of 55 ppm/°C, -55°C to 150°C

Thermal conductivity of 0.65 W/mk

Moisture absorption of 0.01%

UL 94-V0

3.Benefits

Unique ceramic-PPO thermoplastic composite without fiberglass reinforcement

Precisely tunable dielectric constant (3 to 25 range)

Excellent dielectric performance and high reliability

Low dielectric loss with stable frequency response up to 10 GHz

Low moisture absorption and high thermal stability

Suitable for high-reliability military and aerospace applications

4.PCB Details

| Specification | Value |

|---|---|

| Base Material | TP960 |

| Layer Count | Double sided |

| Board Dimensions | 108mm × 96mm (±0.15mm) |

| Minimum Trace/Space | 5/6 mils |

| Minimum Hole Size | 0.3mm |

| Blind Vias | No |

| Finished Board Thickness | 0.6mm |

| Finished Cu Weight (Outer Layers) | 1oz (1.4 mils) |

| Via Plating Thickness | 20 μm |

| Surface Finish | ENIG |

| Top Silkscreen | No |

| Bottom Silkscreen | No |

| Top Solder Mask | No |

| Bottom Solder Mask | No |

| Electrical Test | 100% prior to shipment |

5.PCB Stackup (2-Layer Rigid Structure)

Copper layer 1 – 35 μm

TP960 Core – 0.5 mm (19.6mil)

Copper layer 2 – 35 μm

6.PCB Statistics

Components: 56

Total Pads: 92

Thru Hole Pads: 45

Top SMT Pads: 47

Bottom SMT Pads: 0

Vias: 34

Nets: 2

7.Typical Applications

Global Satellite Navigation System

Missile-borne systems

Fuze technology

Miniaturized antenna

8.Quality Assurance

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class-2

Availability: Worldwide